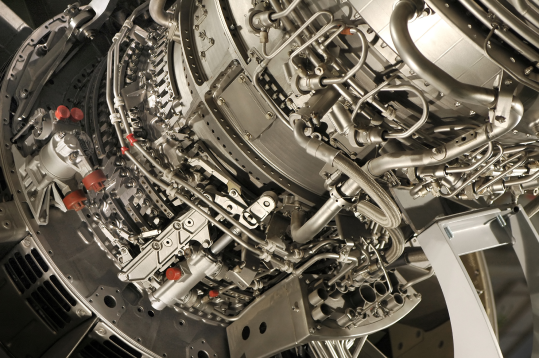

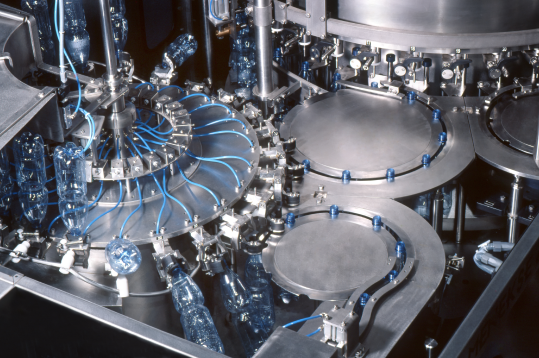

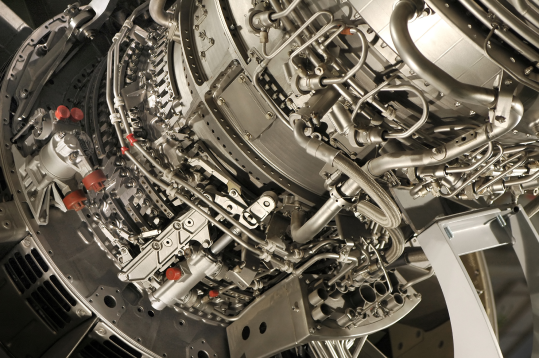

Innomation maintains a specialized, end-to-end assembly facility with several industry-specific purpose-built work areas. This includes a dedicated controlled working environment for the assembly and quality management of sensitive modules. We provide end-to-end assembly services from initial part assembly and inspection to complex packaging, comprehensive quality checking, and delivery straight to the door of our customers.

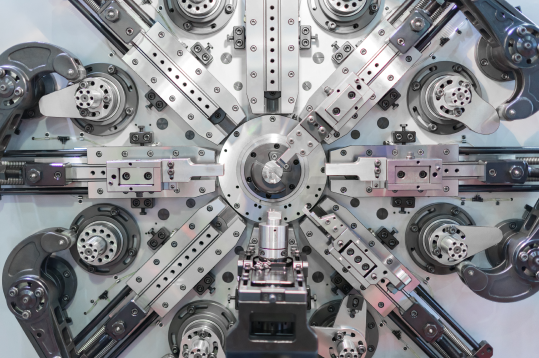

Our facilities undergo regular audits and assessments by third-party certifying bodies to ensure compliance with applicable standards and regulations. In addition to standard quality control measures, such as dimensional inspection and functional testing, we employ advanced validation techniques and simulation modeling, to verify the integrity and reliability of our assemblies under real-world conditions.

Innomation’s precision manufacturing division maintains state-of-the-art manufacturing facilities.